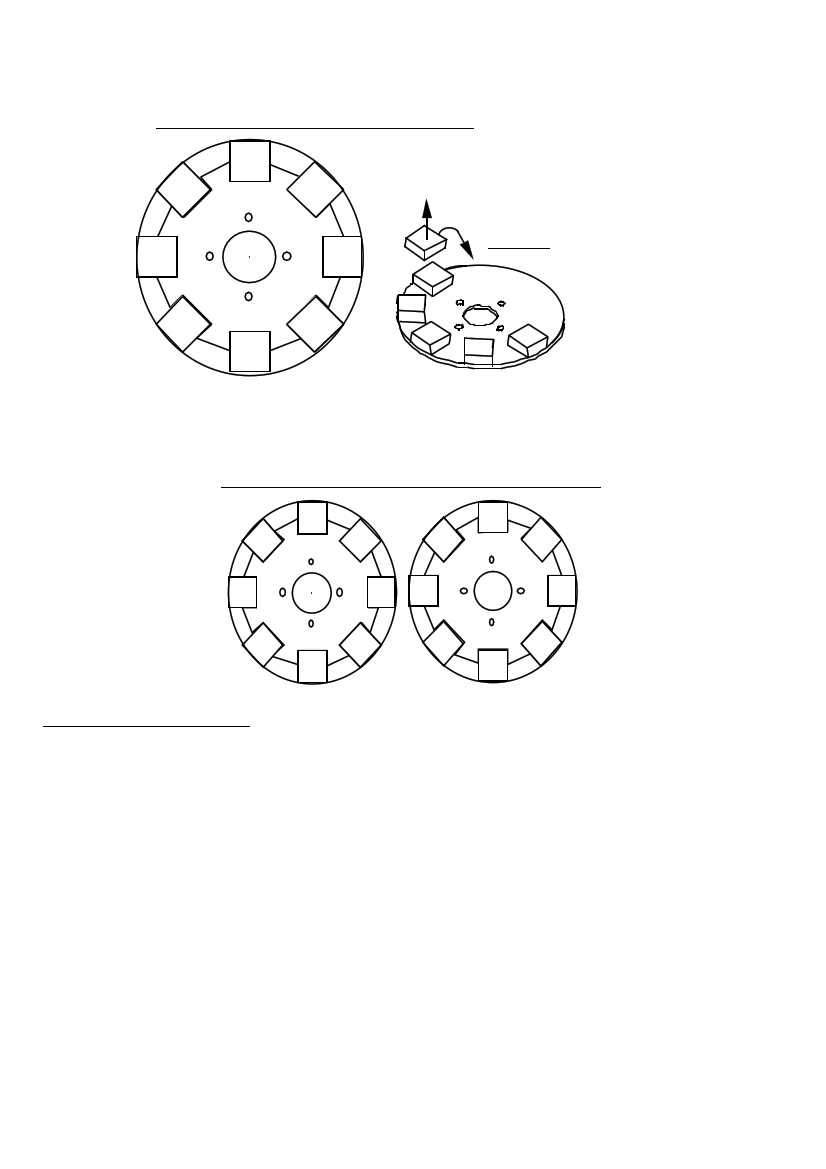

35. PLACING THE MAGNET BLOCKS

N

SS

NN

1. CHECK THAT THE BLOCK IS REPELLED

2. DROP IT INTO PLACE

WITHOUT TURNING IT OVER.

SS

N

The two magnet rotors must attract each other when the mounting holes are aligned.

Check that the magnets next to the holes on one rotor are different from the ones

next to the holes on the other rotor (see diagram 36).

36. THE TWO ROTORS ARE NOT THE SAME

SNS

S

NN

N NS

S

SNS

NN

S

Stainless Steel wire

When the PMG is turning, the magnets will try to fly off the rotors. There is a large

centrifugal force pulling the magnet blocks to fly away. When we started building

these PMGs, the magnet blocks were simply glued to the steel disks. When the PMGs

turned fast, the magnets flew off, and the wind generators were destroyed.

Now we embed the magnets in a resin casting. Resin alone is not strong enough to

hold the magnets. It should be reinforced. Wrap wire around the outside of the

magnet rotors to hold the magnets in. Steel wire is strong enough, but steel would

take the magnetism from the magnet blocks. We use stainless steel because it is

not magnetic and it does not spoil the effect of the magnets. Stainless steel wire

cable is used on fishing boats.

Before using any resin assemble the parts dry. Put the stainless steel rope around

outside the magnets five times, and cut it off with a grinder or chisel. Tape it in

several places so that it is in a coil, ready to drop into place later.

PMG manual

page 33

June 2001